Leave a request. Our specialist will contact you and answer any questions of interest

Submit your application

The Multi-Level Control system from ROBOPAC will maximally reduce the cost of packaging your products due to the automatic multi-level pre-stretching of the stretch film from 150% to 400%.

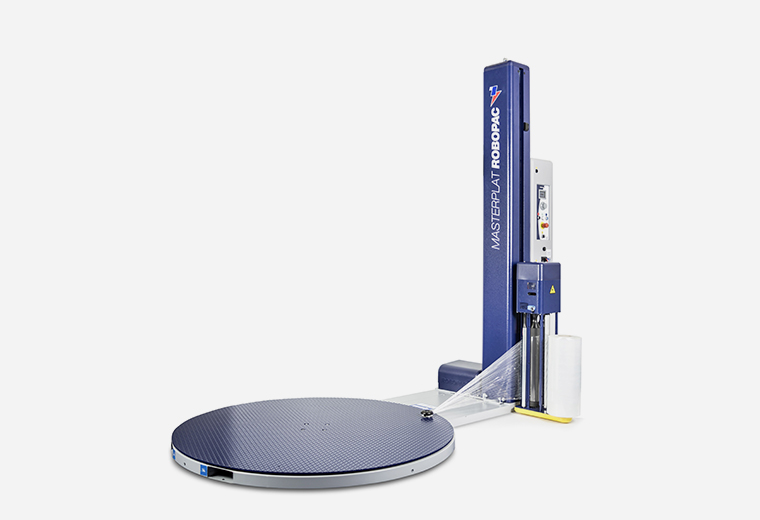

Wrapper for wrapping and moving pallets in an automatic cycle with reduced investment costs. The machine’s rotation system consists of a toothed thrust bearing supported by a ball bearing and transmission through a pinion. The speed of rotation during acceleration and deceleration is controlled by the inverter to ensure that it stops in phase in any situation.

Rotation speed up to 12 rpm.

Productivity up to 48 pallets / hour

Basic options

Rotary table

Equipped with roller or chain conveyors (optional)

Integrated into the structure of the pallet wrapper and guarantees dust and moisture protection

Designed for unstable products on a pallet, as well as with the option of covering the top (dust and moisture protection cycle)

The narrowing of the stretch film web stabilizes the product on the pallet as efficiently as possible.

Bundling will successfully replace horizontal straps, significantly speeding up the packaging process and reducing costs.

Film pre-stretching carriages

CUBE LEVEL 1

Allows you to stretch the stretch film in the range of 150-400% and adjust up to 12 steps of adjusting the main parameters during the winding cycle.

The system consists of 2 driven rollers rotating at different speeds. The speed of the rollers is automatically adjusted. Film tension adjustment is regulated by analog sensors. When the angle of the pallet is reached, the tension force increases, and the system automatically increases the supply of stretch film to the pallet, decreasing the tension.

Allows you to stretch the stretch film at fixed values up to 350% and adjust up to 12 steps of adjusting the main parameters during the winding cycle.

The system consists of 2 driven rollers rotating at different speeds. The speed of the rollers depends on the gear ratio of the gear pair. A stretch film web passes through the friction rollers, and due to the difference in speed, stretching occurs.

The compensation of the tension force of the stretch film on the pallet is controlled automatically.

| Pallet dimensions min-max mm | 600x800 - 1000x1200 (1400х1400 optional) |

| Maximum height of cargo on a pallet mm | 3000 |

| Supply voltage and frequency V - Hz | 400-415 ± 5% - 50 ± 1% |

| Supply voltage and frequency V - Hz | 380-480 ± 5% - 60 ± 1% (optional) |

| Film bobbin height mm | 500 (Standart) - 750 (optional) |

| Stretch film thickness μm | 17 - 30 |

| Top cover film thickness microns | 40 - 100 |

Automatic pallet wrapper ROTOPLAT 3000

Download

Download

For more than 20 years of work, we have accumulated tremendous experience in marking technologies.

See projects On the market since 1994

On the market since 1994 Эксклюзивный дистрибьютор

Эксклюзивный дистрибьютор Превосходное качество продукции

Превосходное качество продукции

SUPERBOX is a box-forming machine that automatically seals the bottom of a carton with adhesive tape. Model series: 544, 545, 565 Main components ...

In stock

ROBOPAC ECOPLAT PLUS is equipped with a carriage without the possibility of pre-stretching the film – your first step towards optimizing ...

In stock

The main area of application is food production. Product format: cardboard box, cases and trays with film Productivity up to 3 layers / min. (15 ...

In stock

Allows you to pre-stretch the film at fixed values of 150% -200% -250% -300% and evenly apply a layer of film on the pallet – you will ...

In stock

• high-strength timing belts instead of serviceable chains • bearings with pre-lubricated for life • reinforced structure and balance of inertial ...

In stock

STARBOX is a box-forming machine that seals the bottom of a cardboard box using adhesive tape in a semi-automatic mode. Model series: 50, 65

In stock

Application of adhesive tape 25-38, 50 or 75 mm wide Model series: 50, 65, 80 Key features Conveyor system Top and bottom mechanized conveyors ...

Leave a request. Our specialist will contact you and answer any questions of interest

Submit your application